It’s sometimes called New Product Introduction (NPI) or new product planning and development. It applies to tangible products such as phones, coffee makers, TVs, etc., and intangible products like mobile phone apps and software programs.

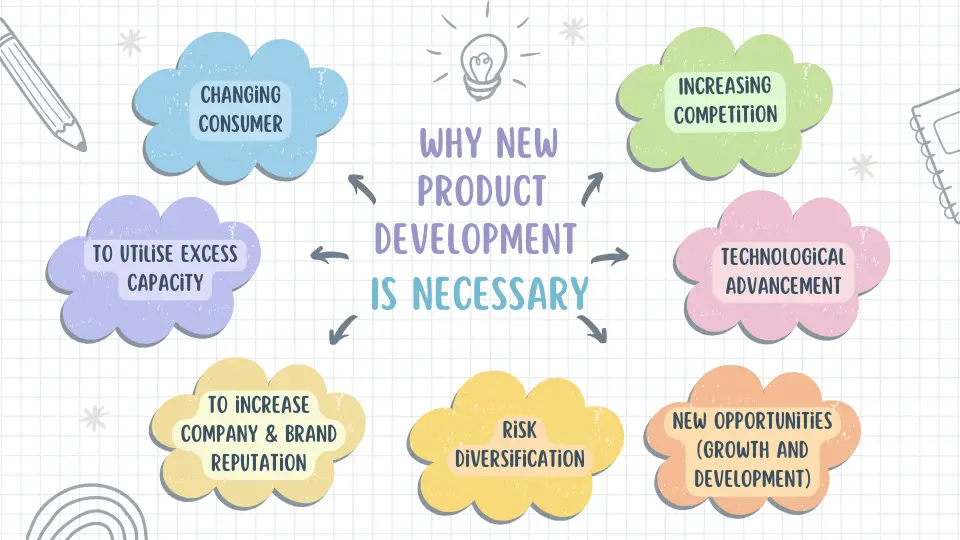

Why is New Product Development necessary?

NPD is the driving force of companies and vital for their organic growth. Insatiable consumer appetite, worldwide solid competition, and changing consumer behaviour and technology force companies to invest in new products to succeed or for their survival.

The importance of introducing new products can be summarised in these “Seven reasons why new product development is necessary.”

A New Product Development (NPD) strategy is a plan or framework that guides creating and delivering a new product to the market. It involves steps and decisions to identify opportunities, conceptualise, design, develop, and launch a product that meets customer needs and aligns with business goals.

Why do you need a thorough NPD strategy? According to the McKinsey Global Institute data, consider these 4 statistical facts about how products are fair.

Research shows that some NPD failures can be attributed to the lack of a structured NPD process. According to Wheelwright and Clark (1992), companies that approach NPD in a structured manner have more success than those with an ad-hoc approach.

Typical NPD processes companies follow can be divided into Structured approach vs. ad-hoc methods.

When developing new products, structured approaches and ad hoc methods have merits and drawbacks.

Methodical Process – A structured approach follows a systematic, step-by-step process. It typically involves stages like idea generation, feasibility analysis, design, development, testing, and launch.

Risk Management – It often incorporates risk assessment and mitigation strategies at each stage, reducing the chances of significant setbacks or failures.

Efficiency – Structured methods can enhance efficiency by providing clear guidelines, roles, and responsibilities. They also make it easier to track progress and make necessary adjustments.

However, structured approaches can sometimes be rigid, potentially stifling creativity or innovation. They might also require more time and resources upfront. Typically

Flexibility and Creativity – Ad-hoc methods allow for more flexibility and spontaneity. They can adapt highly to changing circumstances, enabling quick pivots or adjustments based on emerging opportunities or feedback.

Cost and Time – They may save time and resources initially by skipping formalities and allowing for rapid prototyping or testing. This agility can sometimes lead to faster product iterations.

However, ad-hoc approaches need consistency, increasing the risk of overlooking critical steps or making hasty decisions. They also result in inefficiencies due to the absence of a defined structure.

The ideal approach often involves balancing structured and ad hoc methods. Incorporating structured steps ensures essential considerations are addressed while allowing room for flexibility to encourage innovation and adaptation.

For instance, using a structured approach for the core development process while allowing for creative brainstorming sessions or agile methods during certain stages can combine the benefits of both approaches.

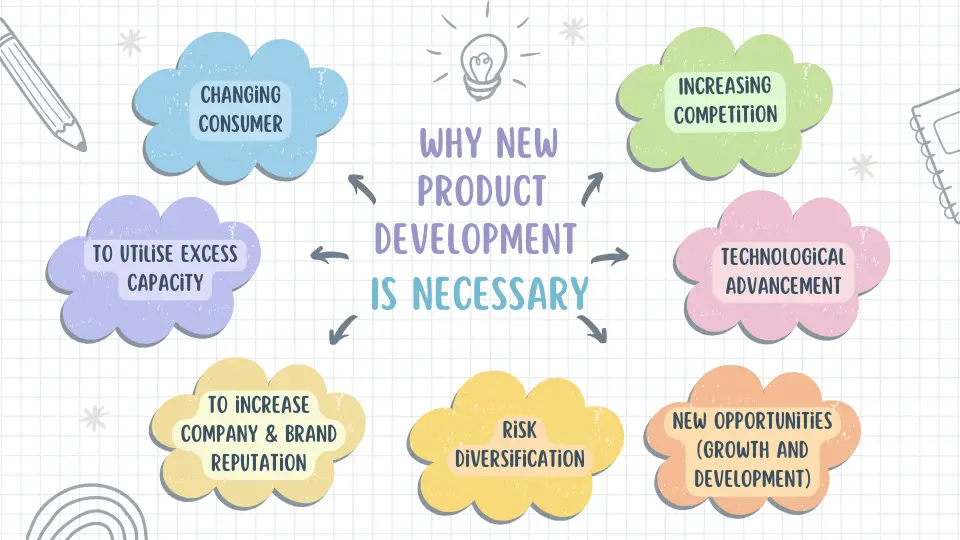

A well-tailored NPD strategy will enable companies to organise their product planning, understand their customers, accurately plan, and efficiently use their resources for NPD. An NPD strategy will also help to avoid the pitfalls mentioned above and increase the chance of product success.

| Models | Phases |

| Roozenburg & Eekels, 1995 | Analysis – Concept – Materialisation |

| IEC60300-1 | Concept and definition – Design and development – Manufacturing and installation |

| Fox, 1993 | Pre-concept – Concept – Design – Demonstration – Production |

| Pahl & Beitz, 1996 | Clarification of task – Conceptual design – Embodiment design – Detail design |

| Cooper, 2005 | Scoping – Build business case – Development – Testing and validation – Launch |

| Blanchard, 2004 | Conceptual design – Preliminary system design – Detailed design and development – Construction – Production |

| Pugh, 1990 | Market – Specification – Concept design – Detail design -Manufacture |

| Andreasen & Hein, 1987 | Recognition of need – Investigation of need – Product principle – Product design – Product preparation – Execution |

New product development methods

| Framework | Year | Key Concepts/Approach |

| Roozenburg & Eekels, 1995 | 1995 | Emphasises systematic design processes, including problem definition, conceptual design, and embodiment design. |

| IEC60300-1 | Not specific | Provides guidelines and principles for quality management and reliability in product development. |

| Fox, 1993 | 1993 | Focuses on integrating design with manufacturing, considering manufacturing constraints during the design phase. |

| Pahl & Beitz, 1996 | 1996 | Proposes a systematic design approach with methods for problem-solving and product development. |

| Cooper, 2005 | 2005 | Introduces the Stage-Gate model, emphasising stages and decision gates to manage the NPD process effectively. |

| Blanchard, 2004 | 2004 | Primarily focuses on engineering design processes and principles, including reliability and safety. |

| Pugh, 1990 | 1990 | Introduces the concept of decision matrices and Pugh matrices to aid in the evaluation and selection of designs. |

| Andreasen & Hein, 1987 | 1987 | Emphasises using systematic design methods to achieve innovation and address user needs effectively. |

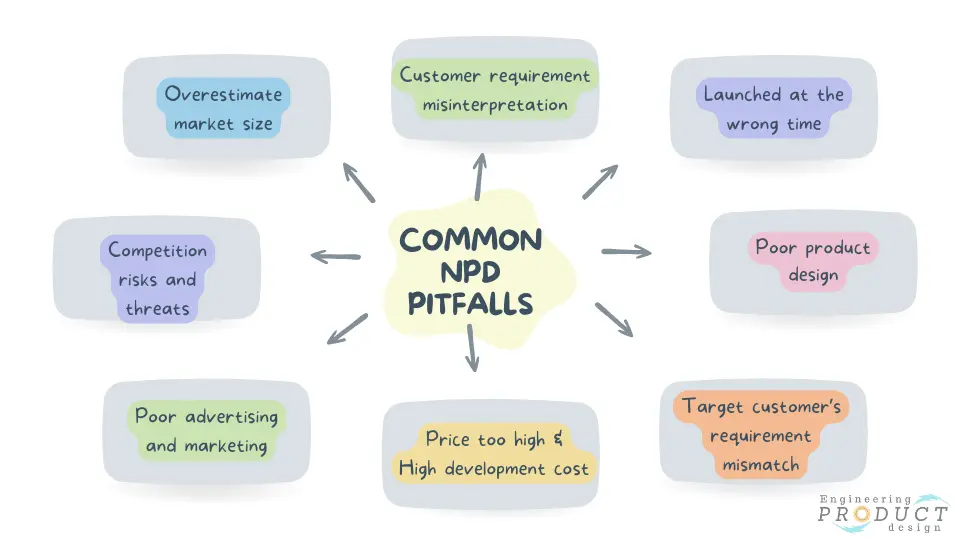

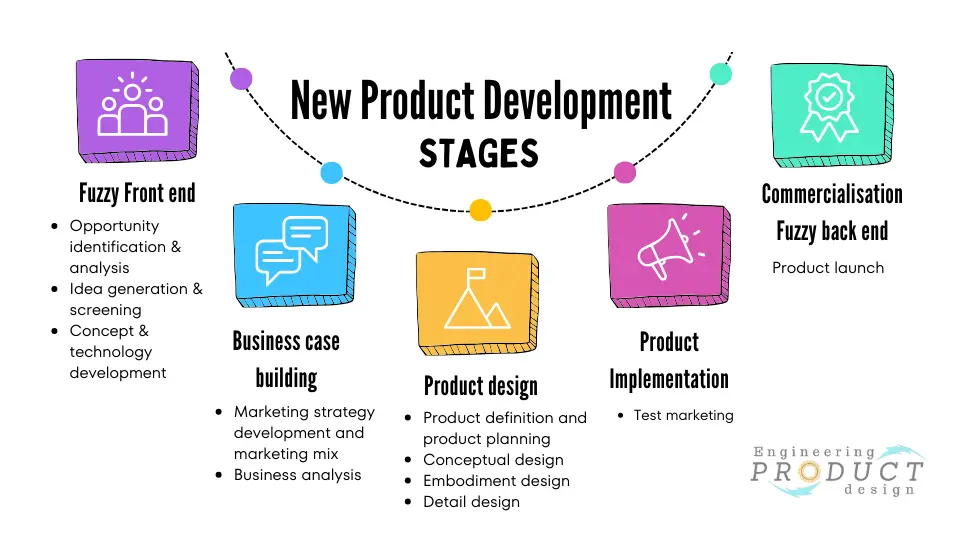

There are various models proposed by authors before. Still, it starts with an idea to build a product that meets the customer’s technical specifications. It ends with a product launch or introduction to the market. The number of stages and phases and their description varies from model to model depending on the following.

As the table above shows, the product development stages can vary, but they often can be grouped into these 5 key phases, which include 8 critical activities;

As the name suggests, the fuzzy front end is the messy stage of the new product development where opportunities are identified & analysed, and ideas are generated & screened before a viable concept is developed. This set of activities paves the way for a formal technical specification of the final product.

This stage analyses the market before product design and development begin. Marketing strategy development defines the target market, sales, and market share. The company must also determine the best market mix ( 4Ps—product, place, price, and promotion). Finally, the company evaluates the proposed product’s attractiveness against its long-term objectives.

The product design stage is the detailed phase where the technical requirements are turned into an engineering product design. In engineering, prototyping and product design are at the heart of any product development and follow the following four phases.

Market testing – The stage at which the product is introduced using the proposed marketing program. It lets the company test the product and its marketing program—targeting and positioning strategy, advertising, distribution, pricing, branding and packaging, and budget levels.

After the product implementation phases, management will have gathered all the relevant information to make the final decision about going commercialisation. At this stage, companies use the knowledge gained from the product implementation stage and their marketing mix to launch the product, where product life cycle management starts.

In New Product Development (NPD) methods, several factors influence each stage of the development process. These factors can shape decision-making, resource allocation, and overall success. Here are some key factors that have an impact:

The interplay of these factors differs across industries and products, requiring flexibility and adaptability in the NPD process. Companies that effectively navigate these influences often produce products that are not only innovative but also aligned with market demands and regulations.

In New Product Development (NPD) methods, several factors influence each stage of the development process. These factors can shape decision-making, resource allocation, and overall success. Here are some key factors that have an impact:

Market Trends and Consumer Needs – Understanding market trends and evolving consumer needs is crucial. These insights guide idea generation and concept development and ensure the product meets customer expectations.

Technological Advancements—Technology influences product design, development, and production methods. Staying abreast of new technologies helps create innovative products, improve efficiency, and enhance competitiveness.

Regulatory and Compliance Requirements – Legal and regulatory standards impact product development, especially in healthcare, food, and automotive industries. Compliance with safety, environmental, and industry-specific regulations is essential.

Competitive Landscape—Analyzing competitors’ products and strategies is vital. It helps identify market gaps, differentiate products, and create unique value propositions.

Resource Availability and Constraints – The availability of financial resources, skilled personnel, technology, and infrastructure affects the speed and scope of product development. Constraints in any of these areas can influence decision-making and the development timeline.

Risk Management and Feasibility – Assessing risks associated with new product development is crucial. Factors like technical feasibility, market acceptance, manufacturing challenges, and financial risks need careful consideration at each stage.

Cross-functional Collaboration – Collaboration between departments like R&D, marketing, production, and sales is essential. Effective communication and collaboration streamline the NPD process and ensure a holistic approach.

Customer Feedback and Testing—Gathering feedback from potential customers through surveys, focus groups, and prototypes influences product refinement. Testing helps validate ideas and ensure that the product meets customer expectations.

Time-to-Market Considerations – Speed is often critical in launching a successful product. External factors like seasonal demands or technological obsolescence might necessitate quicker development and launch.

Sustainability and Environmental Factors – Considerations about sustainability, environmental impact, and societal values are increasingly important. Consumers often favour products that align with sustainability goals and ethical standards.

The interplay of these factors differs across industries and products, requiring flexibility and adaptability in the NPD process. Companies that effectively navigate these influences often produce products that are not only innovative but also aligned with market demands and regulations.

The future of product development is shaped by several transformative trends influencing how products are conceptualised, designed, manufactured, and brought to market. Some of these trends include:

Advanced Technologies Integration

Sustainable and Eco-friendly Products

Mass Customization

Collaborative and Agile Development:

Additive Manufacturing (3D Printing):

Remote Work and Digital Collaboration:

Emphasis on User Experience (UX) and Design Thinking:

Predictive Analytics, Product Analytics, and Data-Driven Decision-Making:

Subscription-Based and Service-Oriented Models:

Supply Chain Resilience and Localization

Embracing these trends allows companies to stay competitive, respond to evolving consumer demands, reduce time-to-market, and create products that align with changing societal, environmental, and technological landscapes.

There is more than one reason why companies should create new products . Developing quality new engineering products consistently and having a stronghold in your niche market is one of the most powerful but difficult activities in business (Clark and Wheelwright 1995). 75% of new product developments fail, which shows how challenging it can be for the new engineering product design team to succeed.

Product designers face various challenges during the development cycle, however, not all of them are technical. Some of the challenges are due to external factors such as cost, economic changes, competitor influence, company policy etc.

Let’s look into some of the key general non-technical challenges that product design engineers face in detail.

As an engineering product designer, one of the hardest things is to justify the decisions and manage trade-offs during the embodiment design stage.

For example, a car can be made to look like the BMW concept car and also made lighter, faster, more efficient etc, but all these would probably increase manufacturing cost and the car will cost more than the targeted segment of the market can afford. Hence, to keep the unit selling cost down, compromises have to be made to the original product requirement specification without sacrificing some of their original unique selling points. The challenge here is to identify, understand and manage such trade-offs in a way to increase the product’s success.

Product economics is all about profitably developing and selling an engineering product to solve a customer’s problem.

Every product designer who had to make a trade-off decision would know that the decision was made most probably due to economics. The 8 stages of new product development require a large investment and a lot more effort than you think at the start. To get a reasonable return on investment, the end product must be both appealing to customers and relatively inexpensive to produce.

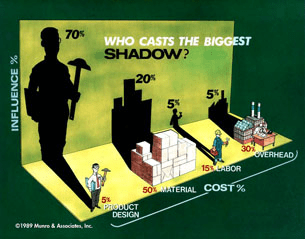

As the cost breakdown shows in image above on average an engineering product design accounts for only 5% of the total NPD cost but its influence on the rest is 70%. Even a simple design for assembly (DFA) change of using snap-fits instead of self-tapping screws can save thousands of pounds. No matter how simple the product is, there will be hundreds of such decisions that would have an impact on the final selling price.

Thus, the challenge is to make the correct decisions during the product design stage so that subsequent costs (material, labour & overheads) can be kept to a minimum.

Due to globalisation and international marketplaces such as Amazon, eBay, Alibaba, etc., the global market can be accessed from anywhere in the world. Global competition is one of the biggest challenges companies face during product development due to this large and diverse marketplace.

A company could start developing an engineering product unaware that an overseas competitor is already halfway through theirs.

Here the challenge is to design and develop a product to launch at the right place and time for the right price before your competitors.

Most technology-driven engineering product design companies compete on NPD cycle time, so they can launch the product first in the market. This was highlighted by Stalk’s (1988) term “time-based competition”.

Due to this global competition, the entire new product development from concept to market launch is often carried out to a very tight delivery schedule.

Without the time pressure, product design technical challenges can be managed, but due to the tight schedule technical issues have to be resolved and decisions made quickly.

Hence the challenge is to make the managerial decisions to avoid project overrun without compromising the design specification within the specified timeframe.

Although the product design and development duration depend on the product type and the industry, in general, it’s safe to say that it takes on average 9 – 12 months. It would take longer if the products need approval for FCC, CE etc.

In this period, technologies advance, customer needs change and evolve, competitors introduce similar products and the economic environment shifts.

Hence, the challenge is to make crucial decisions promptly and invest money in a constantly changing environment to succeed.